Looking for ways to create an exceptional, unique facade?

The search for the icing on the cake is now over. Our laser technology enables us to leave nothing to be desired. From now on you can let off steam on your facade as you wish and play with shapes and patterns according to your own ideas.

- Shape and freely selectable from 3,000 possible colours

- All-round coating

- Infinite perforation without frame subdivision

- Expressive whether in your own or in a standard design

01. References

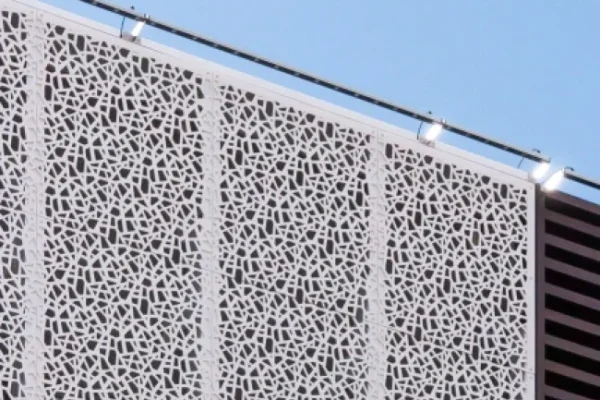

Unique Floral Design

Perforated Facades Sliding, Folding & Shading Elements

There is no Second Chance for the First Impression

Perforated Facades Sliding, Folding & Shading Elements

An Office Building in Korydalos (Greece) that Stands out in Design Terms

Perforated Facades

Perforated Facade with Tree-Inspired Design

Perforated Facades

Residential Units with Impressive Architecture for a Great Living Experience

Perforated Facades Balcony Railings

An Office Building in Korydalos (Greece) that Stands out in Design Terms

Perforated Facades

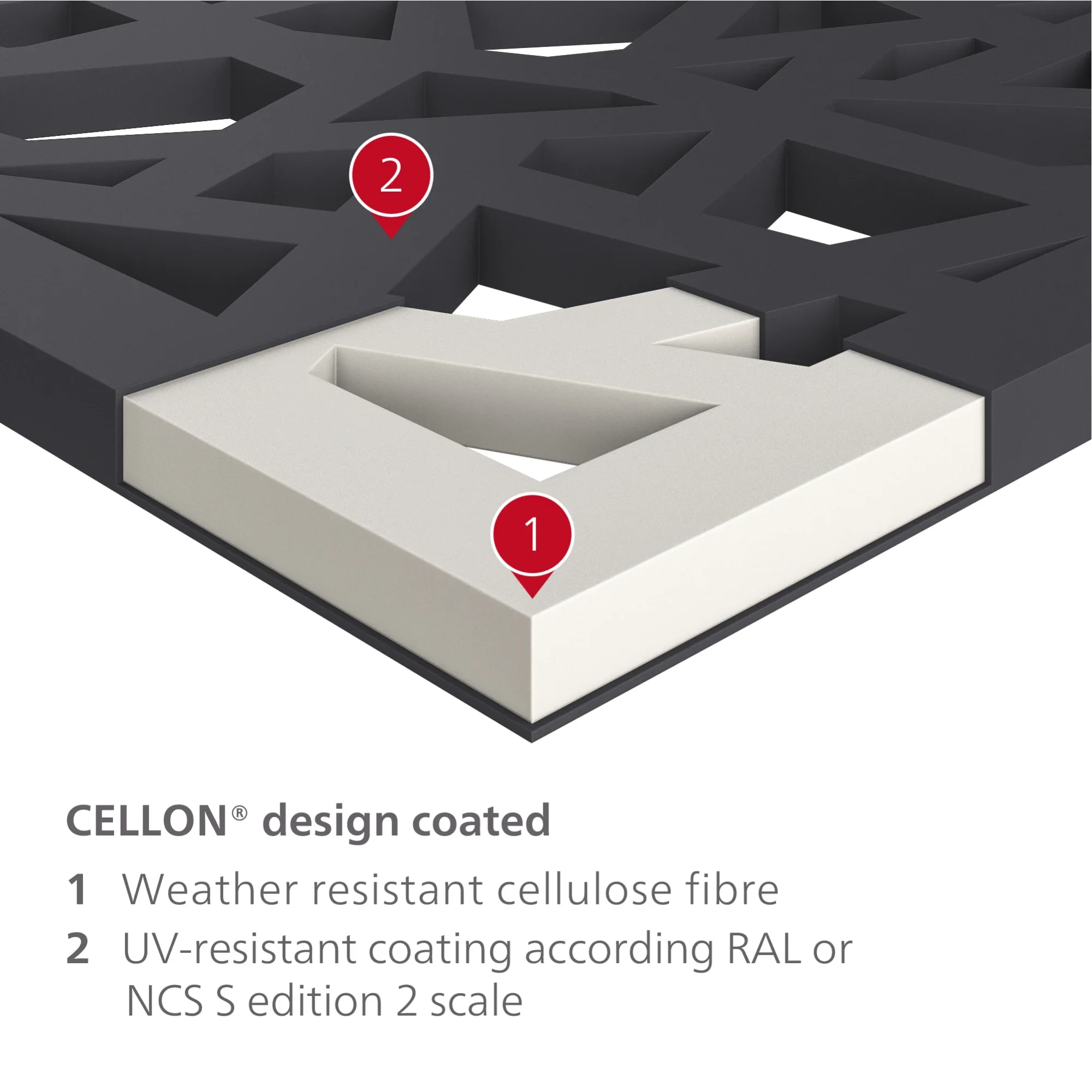

02. Material

Our CELLON® panel is a high-pressure laminate panel (HPL Compact or solid core panel) consisting of 70% cellulose webs and 30% phenolic resin. The extremely weather and frost-resistant material is ideal for outdoor applications.

The HPL panel convinces with absolute moisture resistance and minimal expansion. In contrast to conventional HPL panels, CELLON® is characterized not only by the variety of shapes and colors available, but above all by its natural appearance. The colour is applied directly to the resin and thus the top layer, which means that the sterile resin surface does not stand out, but rather the selected color concept is ideally emphasized.

Thickness:

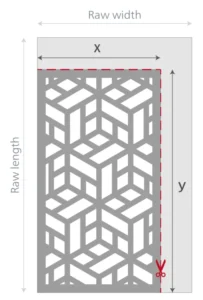

Formats

The raw panels are project-specifically cut to the desired dimensions using laser technology (including drill holes). You choose the width (x) and the length (y) of the panels individually. Do you want round cuts or additional cut-outs? Simply draw them in your DXF plan and they will be manufactured to size.

Please consider the following raw panel formats for waste optimisation:

perforated panels

CELLON® design

raw width | raw length |

|---|---|

| 1200 mm 1280 mm | 2400 mm |

*Only this format is also available with a decor surface in stone or wood look.

03. Colours and Surfaces

perforated facade panels are available in 3,000 colours. In addition to RAL, NCS S and metallic colours (IGP. Bruag Alu, DB), there is also a wide selection of decors in stone or wood.

04. Design

The cutting by laser makes it possible to design the panels completely individually. Draw your own design or choose a pattern from our design collection specially optimized for facade applications.

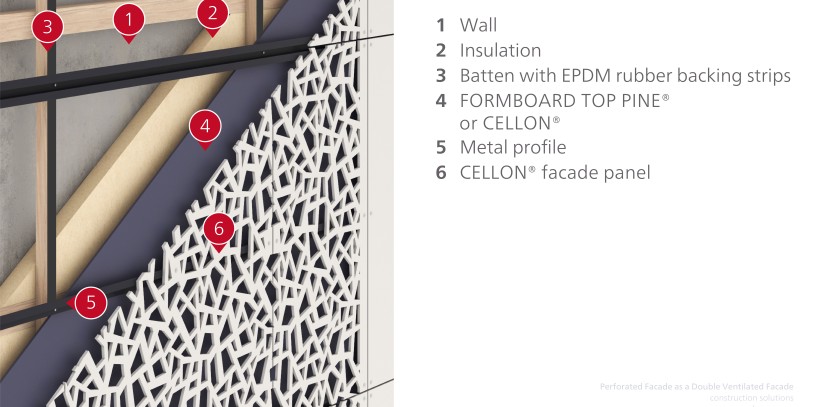

05. Construction Solutions

Due to the open areas of a perforated facade made of CELLON® , the layer behind it may have to meet higher requirements such as wind and weather protection. Should the normal stress be exceeded, the following common facade systems can be used:

UV-resistant Facade Membranes

as a Double Ventilated Facade

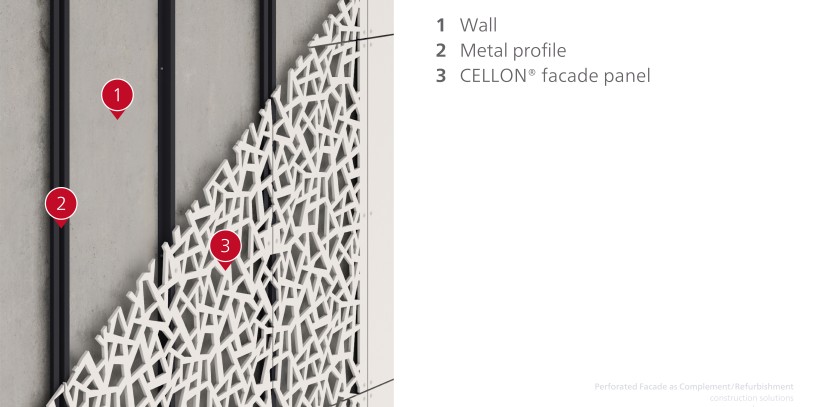

as Complement/Refurbishment

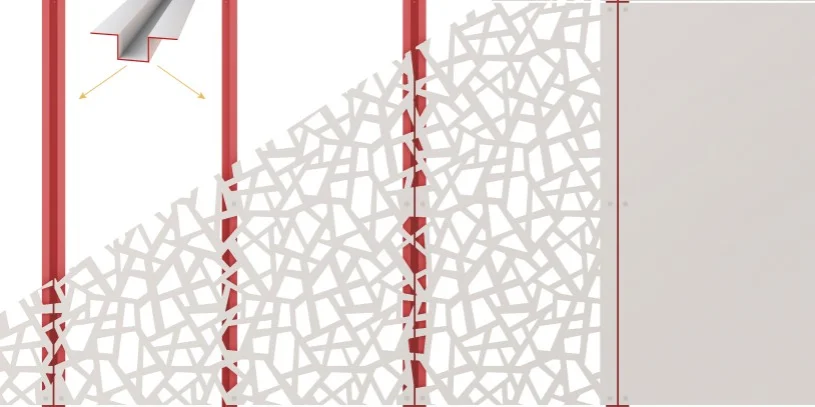

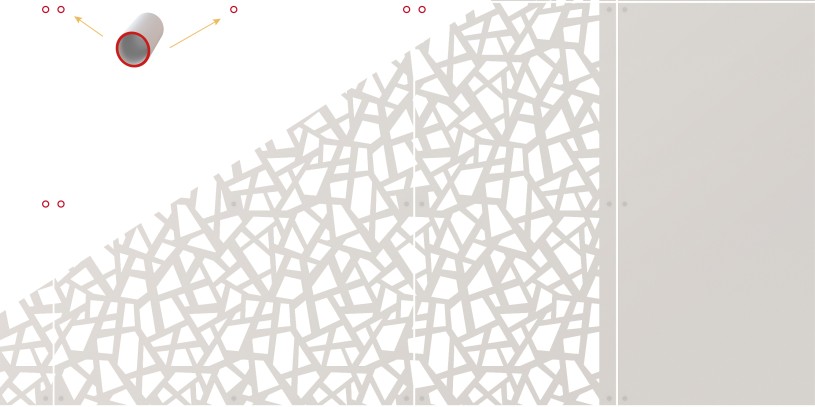

The design of the perforated façade can run through the entire façade surface and does not necessarily have to be interrupted in the construction areas. Depending on the design, it may be that the substructure becomes visible through the openings, which can disturb the perception of the image. To avoid this, either the panel can be highlighted by a strong contrast to the substructure and the wall or only a punctual attachment can be used.

Example of a Visible Substructure:

Example of an Invisible Substructure:

Perforated facades can be executed by various constructions. Additional options are described in the technical data sheet for perforated facades.

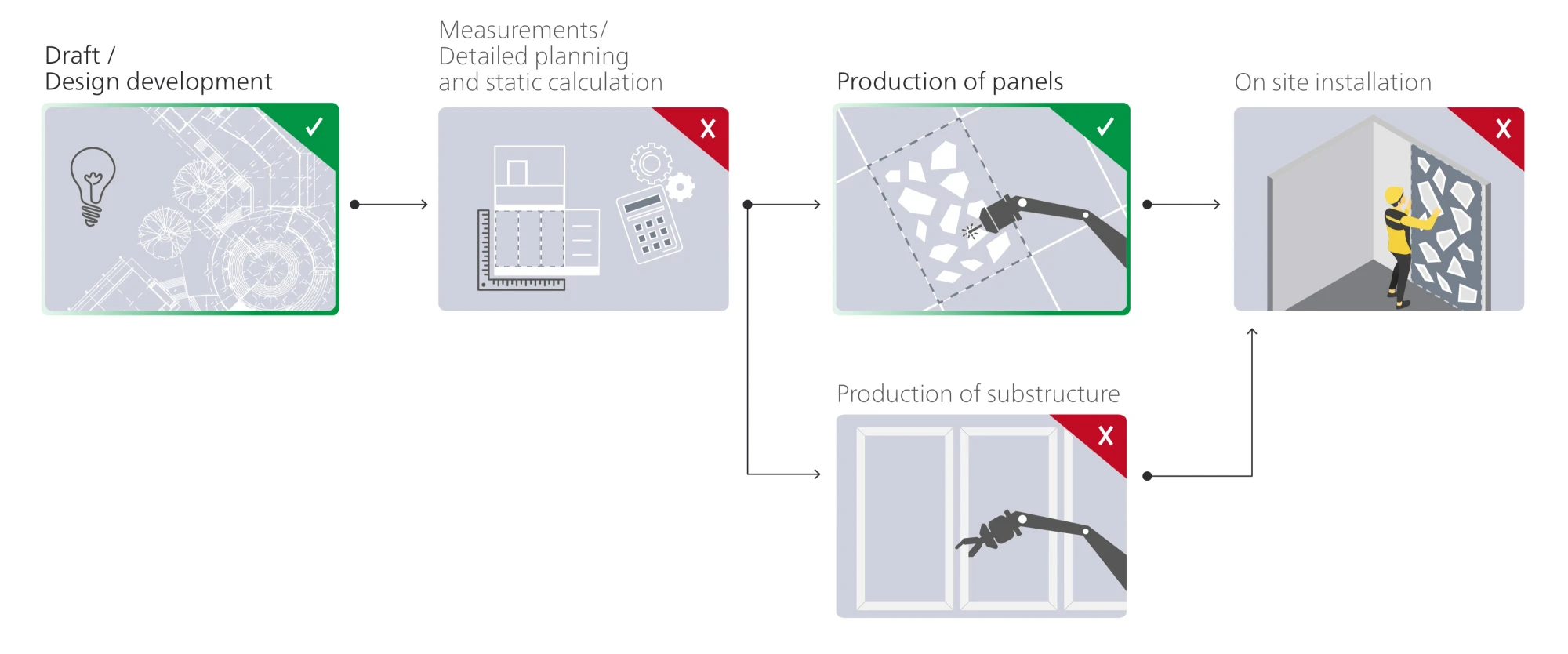

06. Project Procedure

The perforated facade is the design highlight of your building. For this reason, we already provide support in the design phase with our many years of experience and in the preparation of the tender texts. The division and dimensioning of the substructure is carried out by the qualified facade construction company in cooperation with the civil engineer. He also does the dimensional checks on site and the installation. We deliver the panels ready for installation to the craftsman’s company but do not install them by ourselfs.

Summary:

Buildings as unique as their inhabitants. A building as individual as its owner? Delicately-perforated facade elements quickly make a building eye-catching. The balustrades made by Bruag from solid core panels using flexible laser-cutting technology and employing an enormous range of colours will enable you to give your building an individual feel too – without going to any great lengths.

Humans are unique. Two men looking exactly the same? Not possible. Unfortunately that is not true for buildings. All too often, newly built structures offer little differentiation. With a perforated façade by Bruag, this won’t occur to your building. Besides a broad variety of standard perforations, our production allows us to produce a perforated panel exactly according to your imaginings. It is possible to include your sign, your lettering or even to include your very own ornament or mashrabyia.

Let yourself be inspired by projects that have already been implemented or go on to the technical information sheet for perforated facades, the brochure for all outdoor applications or our perforation collection with design templates. In addition to the almost unlimited variety of shapes, there is also a very large selection of color options.